Homogeneous Powder Mixtures

A comparison between dry mixing and wet mixing followed by spray drying

Co-authored by: Daniel Borrelly, Shyann Mattis and John Hageman

This article provides some illustrations of the characteristics of two different mixing methods for powders. One method is dry mixing and the other is wet mixing followed by spray drying of the mixed slurry.

Dry mixing is a very straight-forward process, where the dry ingredients are simply mechanically mixed using several types of equipment as Powder Processing & Technology (PPT) and CinChemPro (CCP) do.

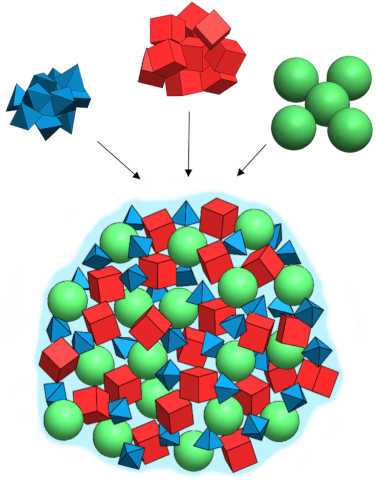

Dry Mix: Illustration of the dry mixing of 3 materials

The other method proposed here is to mix the powders into a liquid slurry. This way, all of the ingredients are added into water and the mobility of the individual particles in this slurry is higher compared to a dry mixing process.

Going beyond just a mix of powders, wet mixing accepts different forms of raw materials, such as powders, liquids, suspensions, and/or colloids, giving more flexibility to the formulation.

Wet Mix: Illustration of the wet mixing of 3 materials

After the wet mixing is done, this slurry has to be dried, so we propose spray drying as an effective method. The reason being is that the droplets formed through the atomizer wheel or spray nozzle will lead into granules containing the exact formulation made in the slurry.

Spray Drying: Illustration of a granule formation inside a spray dryer

As each granule contains the original formulation, we can consider that the homogeneity of the final product stays consistent, even if the separation of the coarse and the fine granules occur in a two-way or three-way collection system spray dryer (chamber, cyclone, and dust-house).

In conclusion, wet mixing of the materials into a homogeneous slurry followed by spray drying leads to homogeneous granules containing the complete formulation of the slurry, while dry mixing results in a product containing different particles less homogeneously distributed throughout.

About the authors:

Eng. Daniel Borrelly, MSc

Business Development Manager, Specialty Chemicals

Shyann Mattis

Assistant Development Engineer

John Hageman

Maintenance Engineer

We would like to thank Kim Yim for her support in creating this article.

Powder Processing & Technology, LLC

5103 Evans Ave.

Valparaiso, IN 46383

(219) 462-4141

www.pptechnology.com

CinChemPro, LLC

458 W. Main St.

Batavia, OH 45103

(513) 732-2464

www.cinchempro.com

10/10/2019